Applications

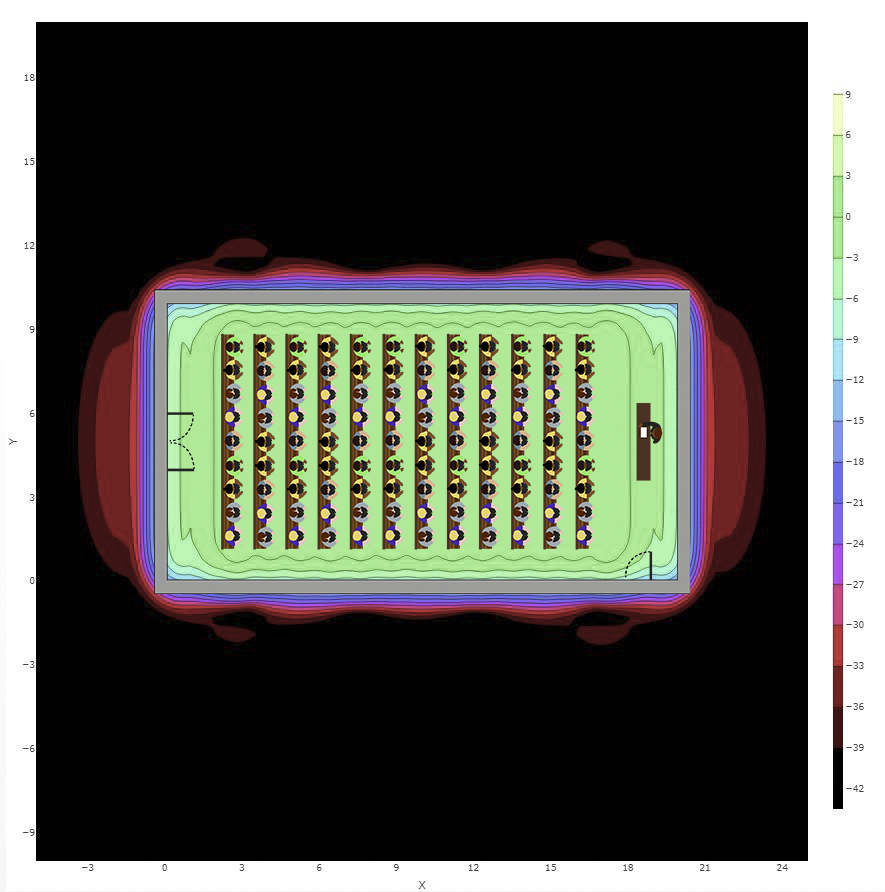

Low-spill means the spill from an induction loop can be restricted to within 1.5m from the edge of the loop area (compared to over 4 times the loop width with a perimeter loop). Similar to the low-loss array, the low-spill array will cover large areas or areas with metal losses.

Description

Two overlapping arrays driven by two amplifiers. Each array has a distribution of different size loop elements along its length.

Comments

The careful design of the variation in size from one loop to the next is what allows spill to be controlled to this degree. Good low-spill loops cannot be designed without access to good simulation tools, however with these tools the design is quick and suitable for most environments. Constant size loops (as in the low-loss array) will not control spill nearly as well in any direction. Ampetronic can carry out this design for you, check your designs for free, or offer you training or advice for designing your own arrays. Using the HLS-2D Metal Loss Test Kit, to deliver a preset output level to give consistent test results, combined with the Loopworks Measure R1 or Ampetronic FSM, provides an ideal aid to quick and simple site assessments.