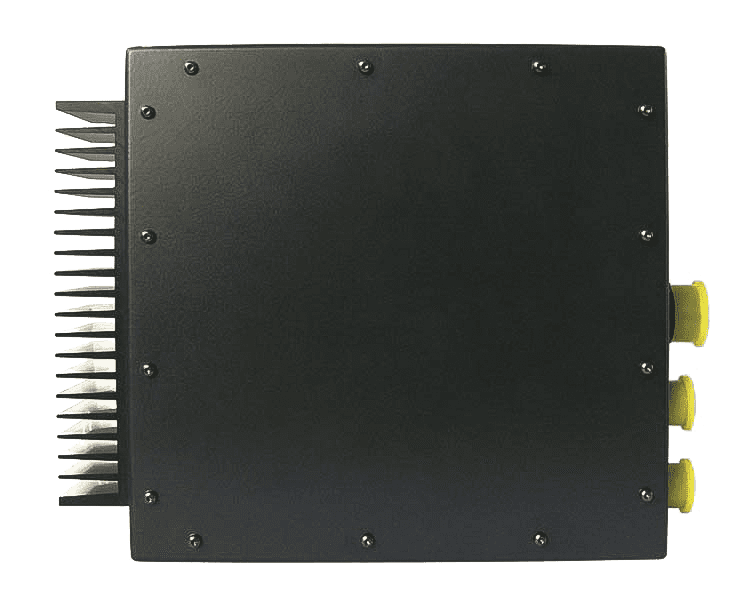

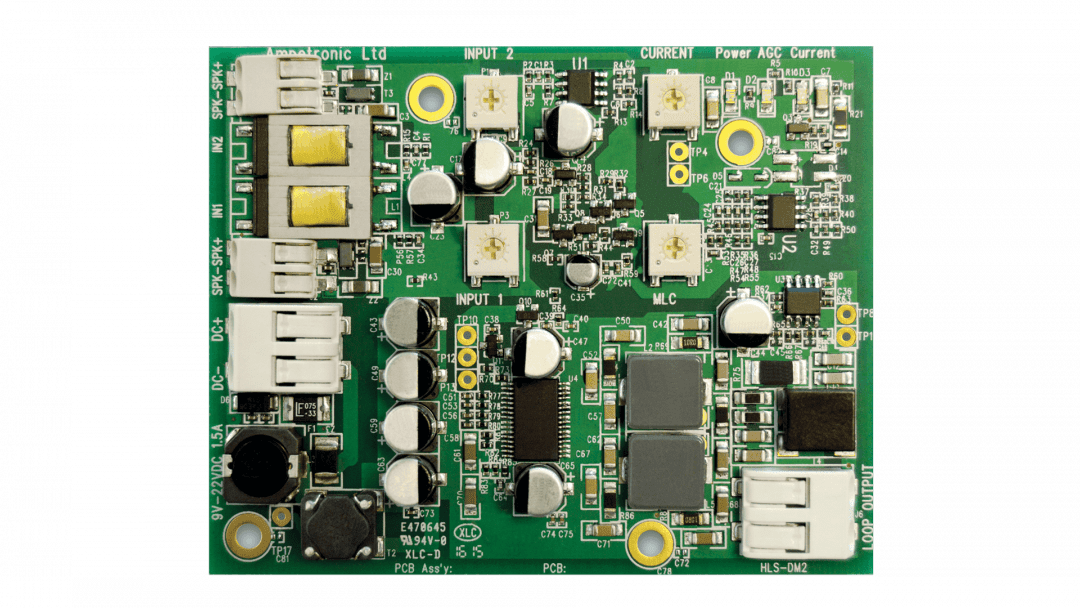

The XA88 is a specialist Hearing Loop driver, designed for use bus, rail and other transport vehicles. The unit is designed for the OEM and vehicle engineering customer, to be integrated into public address and passenger communication systems on board the vehicle. It is backed by Ampetronic’s 5-year warranty and experienced specialist technical support. The unit has two balanced transformer-isolated inputs (for connection to line-level sources or intercom/PA speaker systems), and provides superior sound quality with metal loss frequency response correction. The XA88 meets EMC and environmental standards for use on rail and automotive vehicles. With power supply options to suit many common rail and commercial vehicle power systems, and remote enable and status interfaces for more complex applications, it is the obvious choice for any quality on-board audio system that requires an Audio Induction Loop. N.B. The XA88 Large Transport Vehicle Induction Loop Driver requires a detailed application review by Ampetronic to ensure compatibility with vehicle design for optimum operation.

Applications

- Metro & Underground Rail Systems

- National and Regional Railways

- Trams & Light Rail (LRVs)

- Buses & Coaches

- Boats & Ferries

Product Code: XA88 (A DC power supply option, 24V, 72V, 110V ,will need to be selected when ordering)

Typical Loop Installation

In a rail vehicle or bus, the floor, walls, and roof are all usually metal. To keep away from metal sheets near the plane of the loop (and thereby minimise loss of energy), it is most common to place the loop around the upper part of the wall, typically 1.8m to 2m above floor level. This is usually some 300mm below the roof height. The best location will depend on the exact vehicle design.

Metal Loss

Most transport vehicles have metal construction – the bodyshell is usually metal panels with frames and structural supports. Although the interior may use non-metal panels, an induction loop installed inside such a vehicle will experience significant loss of energy and changed frequency response. The XA88 has sufficient loop drive capacity to overcome the loss of loop signal in most cases. The unit’s metal loss compensation will correct the frequency response up to 4dB/octave slope.

System Testing

Each vehicle design has a different metal construction, and so the metal loss will be different. The only reliable way to determine the metal loss – which determines the loop current – is to measure the performance of a trial loop installation in the same or a very similar design of vehicle. Ampetronic can provide site survey services to help you conduct a trial installation and effectively measure the proposed system’s performance. We can also provide a package of project services, carrying out commissioning or troubleshooting as required. Measurement instruments are available to help you or your customer to regularly test the installed loop’s performance.